We’re committed to providing the highest quality products to our customers. Our success depends on our customer satisfaction. Our overall goal is to achieve 100% customer satisfaction. We strive for excellence and continual improvement in all our activities. We are dedicated and committed to this quality policy. Our parts inspection rooms are climate controlled with regularly calibrated inspection equipment.

KNM Facility Equipment

KNM equipment preview

Facilities Page / Milling Equipment

Kitamura MyCenter H400 Milling Center

- Kitamura control

- Speed 15,000 RPM’s

- 100 Tools Attached

- Table Size: X axis:24″ Y axis: 20″ Z axis: 20″

Akira Seiki V5 XP

- Mitsubishi M645 control

- Speed 12,000 RPM’s

- 28 Tools Attached

- Table Size: 54.0″ x 24.0″

Akira Seiki V4 XP

- Mitsubishi M645 control

- Speed 12000 RPM’s

- 28 Tools Attached

- Table Size: 41.0″ x 21.0″

YCM XV1020

- Fanuc MXP-100i control

- Speed 10000 RPM’s

- 24 Tools Attached

- Table Size: 40.0″ x 20.0″

Lathe

Hass ST-10Y

- 6000-rpm Live Tooling with C axis

- 6.5″ Hydraulic Chuck, A2-5 spindle nose

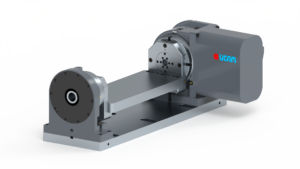

Axis Rotary

Full 4th Axis rotary table

QUALITY ASSURANCE SERVICES

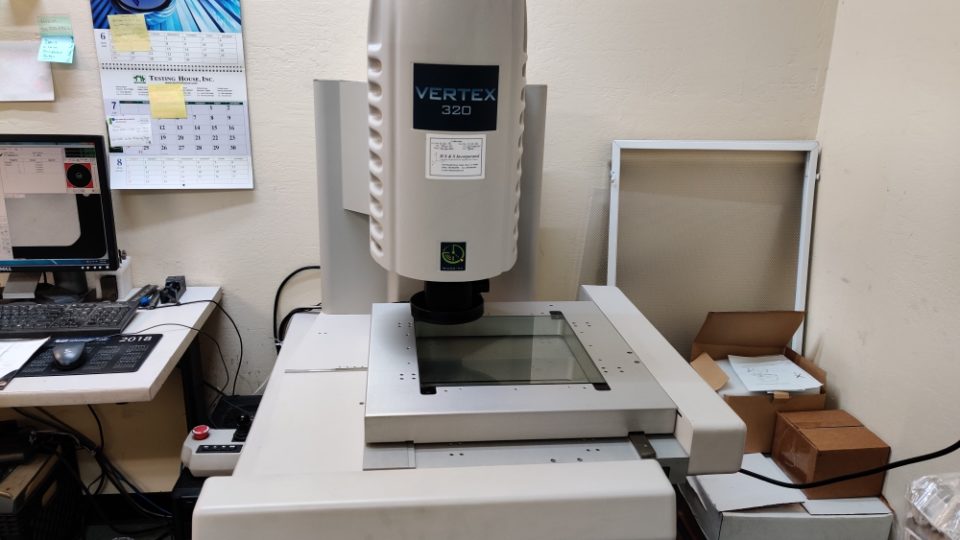

- 1 Vertex 320

- 12.0″x12.0″x6.0″, 12:1 zoom

- The Vertex Automated Vision Machine employs new technology to provide the highest speed and accuracy measuring system.

- Brown Sharpe CMM

- Adixen Helium Leak Check

- Hydro Pressure Testing

- Profilometer

- Optical Comparator

- Height Gauges

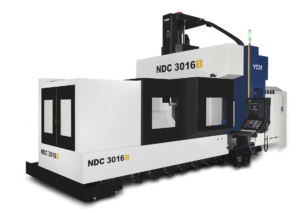

YCM NDC 3016B

- Fanuc MXP-100i control

- Speed 10000 RPM’s

- 36 Tools Attached

- Table Size: 60.0″ x1 20.0″

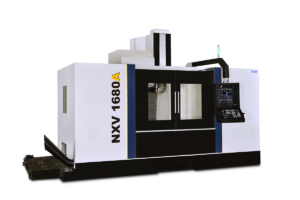

YCM NXV1680

- Fanuc MXP-100i control

- Speed 10000 RPM’s

- 28 Tools Attached

- Table Size: 62.0″ x 40.0″